Why is the Application of Mixed Reality Technology Important for Business?

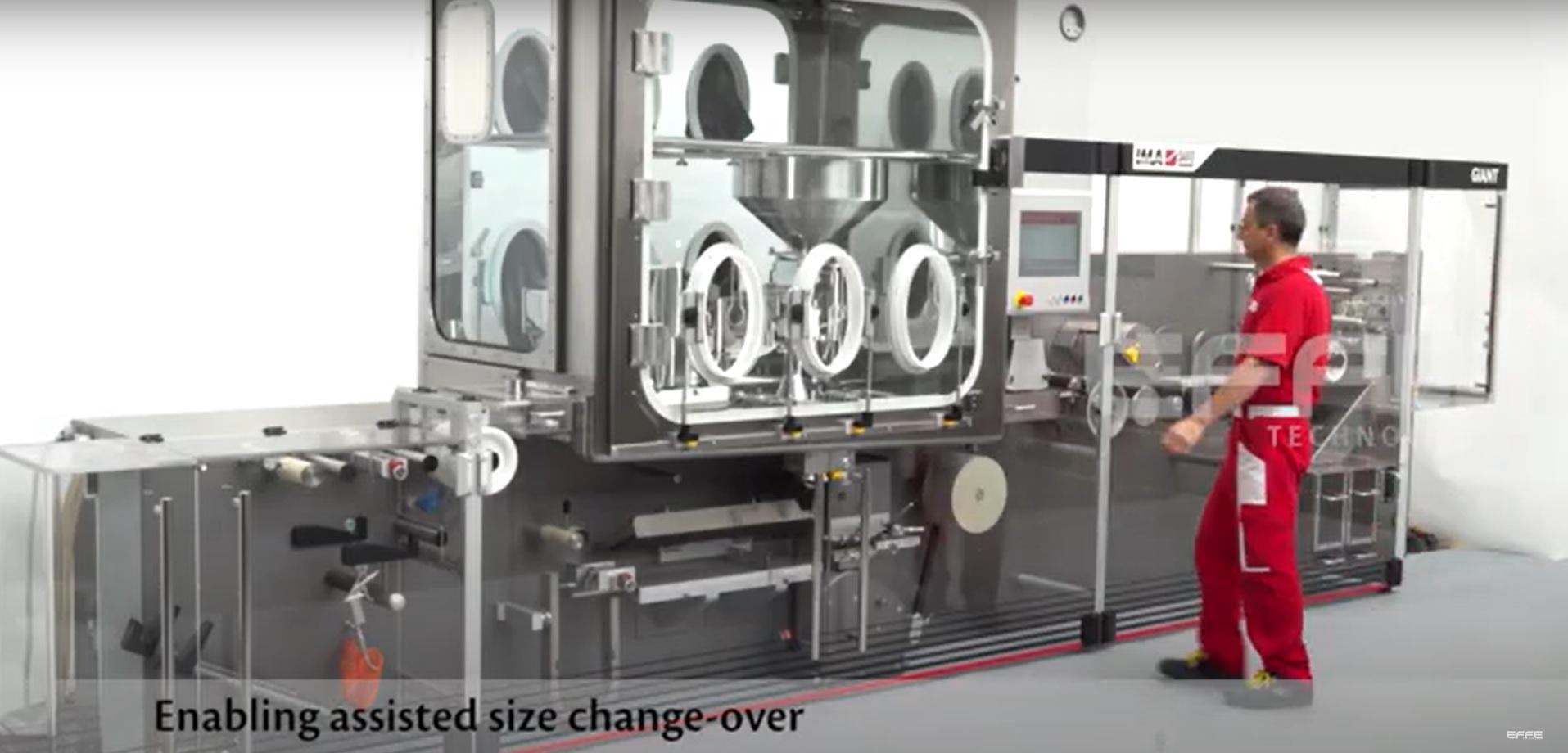

“MR services were critical in EFFE Technology’s response to the need for efficiency and accuracy in today’s competitive manufacturing landscape.” Recognizing the necessity, EFFE set out on a mission to incorporate the capabilities of mixed reality technology into their manufacturing operations. This strategic move centered on addressing difficulties with adjustability, OCR verification, and size changeovers. Adoption of MR services promises significant benefits such as fewer errors, increased productivity, and streamlined operations.”

Compatibility and Specification:

The mixed reality solution from EFFE Technology is designed to be interoperable with a variety of hardware platforms, giving manufacturers flexibility. It connects smoothly with smart glasses, HoloLens devices, and smartphones, making it available to a large variety of users without requiring significant technological changes.

Project Information:

What We Did:

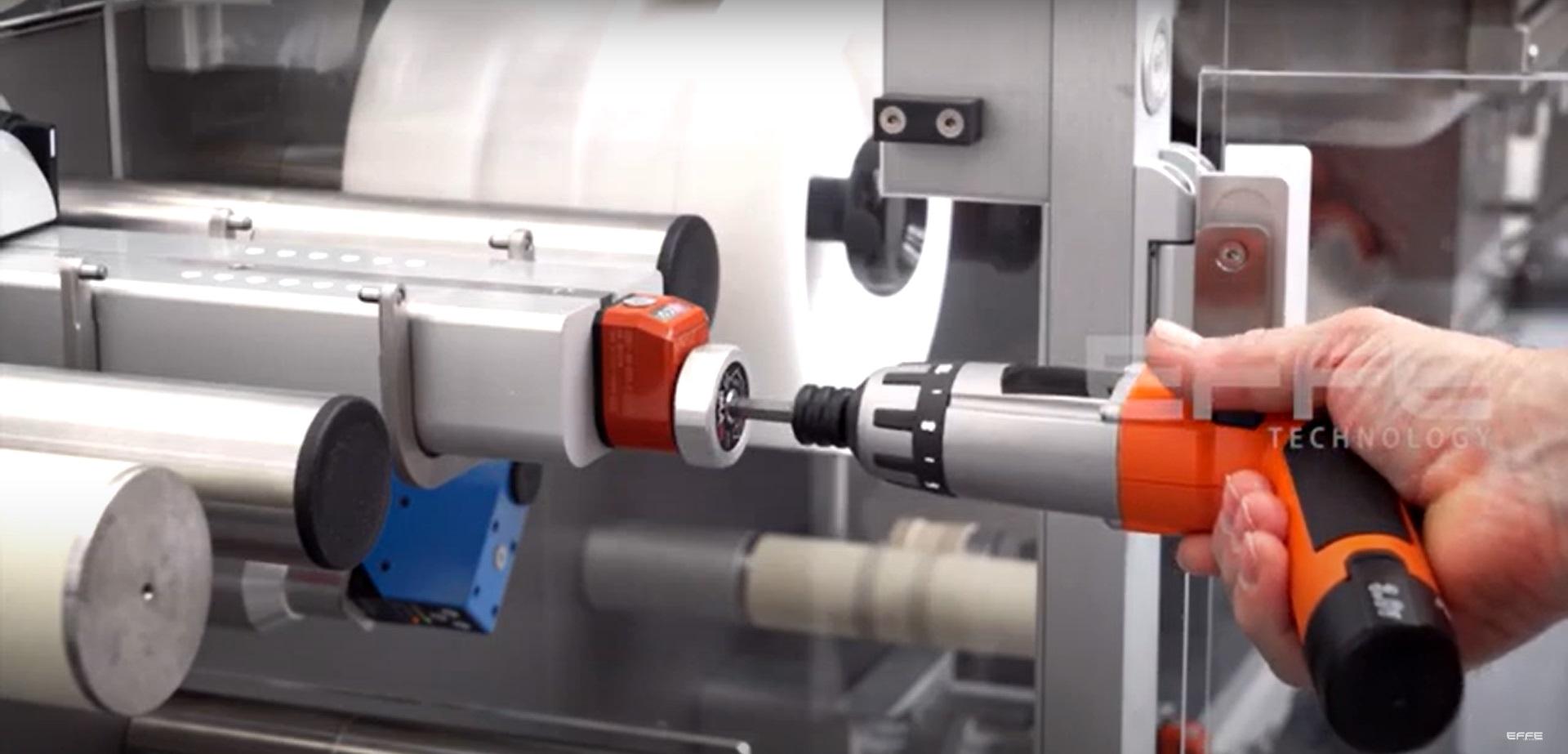

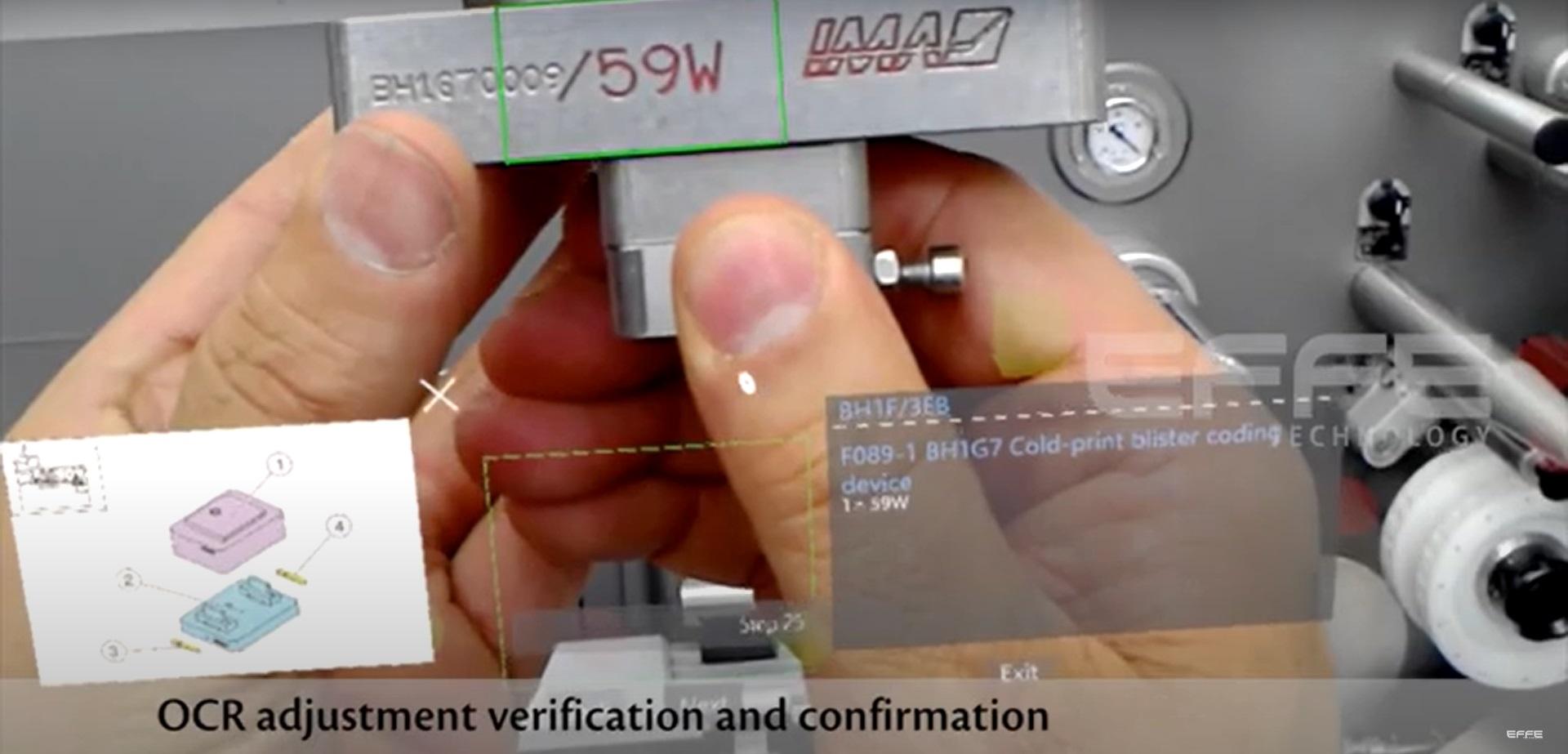

EFFE Technology’s MR services developed a mixed reality application that used real-time data and 3D models to guide production operators. This application provided real-time size changeover aid, dynamic adjustment guidance, and OCR-based verification.

Project Requirements:

A thorough grasp of manufacturing processes, interoperability with current systems, and a user-friendly interface for operators were all necessary. The objective was to reduce downtime and errors while increasing efficiency.

Our Suggestion:

Through visual overlays, the mixed reality software provides real-time adjusting instructions, ensuring precision and reducing errors. OCR technology validated critical data, avoiding manual data entry errors. Size changes were simplified with step-by-step visual instructions, saving downtime and human error.

Our process:

1. Identifying Manufacturing Needs: Determine which areas of manufacturing can benefit from Mixed Reality (MR), such as assembly, training, quality control, and maintenance.

2. Content Development and Simulation:Work with industry specialists to develop exact 3D models and simulations for manufacturing applications.

3. Choosing MR Tools:When picking MR platforms, such as Microsoft HoloLens or specialised industrial MR solutions, prioritise data security and compatibility.

4. User Interface (UI) Design: Create an intuitive MR UI that includes elements such as gesture controls and visual clues to improve usage on the production floor.

5. Tracking Technology: Use tracking technologies such as sensors and markers to ensure that digital information is seamlessly integrated with the physical manufacturing environment.

6. Training and Skill Development: Use MR services to create realistic training simulations that allow workers to safely practise assembly techniques and machinery operation.

7. Remote Technical assistance and Troubleshooting:Use MR for remote technical assistance and troubleshooting, allowing professionals to advise on-site staff through challenging tasks.

8. Continuous Improvement:Update MR applications on a regular basis to match with emerging manufacturing processes and ensure compliance with industry standards.

9. Process Optimisation: Use MR services for real-time process monitoring and optimisation to improve efficiency and reduce production mistakes.

10. Quality Control and Inspection: Improve product quality by utilising MR-enabled quality control technologies that aid in precise measurements and fault detection.

11. Evaluation and Performance Analysis: Evaluate the impact of machine learning on production outcomes such as product quality, labour proficiency, and operational efficiency.

Integrating MR technology into the manufacturing business can result in improved production processes, decreased errors, improved training, and, ultimately, superior product quality and operational excellence by following this thorough procedure. Feel free to visit our partner site. for additional resources and information.

Finally:

The EFFE Technology mixed reality system, which included MR services, changed industrial operations, enhancing accuracy, efficiency, and production. By employing mixed reality services, EFFE was able to perform real-time adjustments, exact OCR verification, and smooth size changeovers, thereby improving their competitive edge in the market. This research shows how cutting-edge technology, notably MR services, may transform traditional industrial processes, paving the path for industry leaders to follow suit. Explore further about the range of services we offer